| City/Town: • Montgomery |

| Location Class: • Industrial |

| Built: • 1906 | Abandoned: • c. 1970 |

| Status: • Abandoned • Demolished |

| Photojournalist: • David Bulit |

Table of Contents

Jenkins Brick Company

John Michael Jenkins, Founder

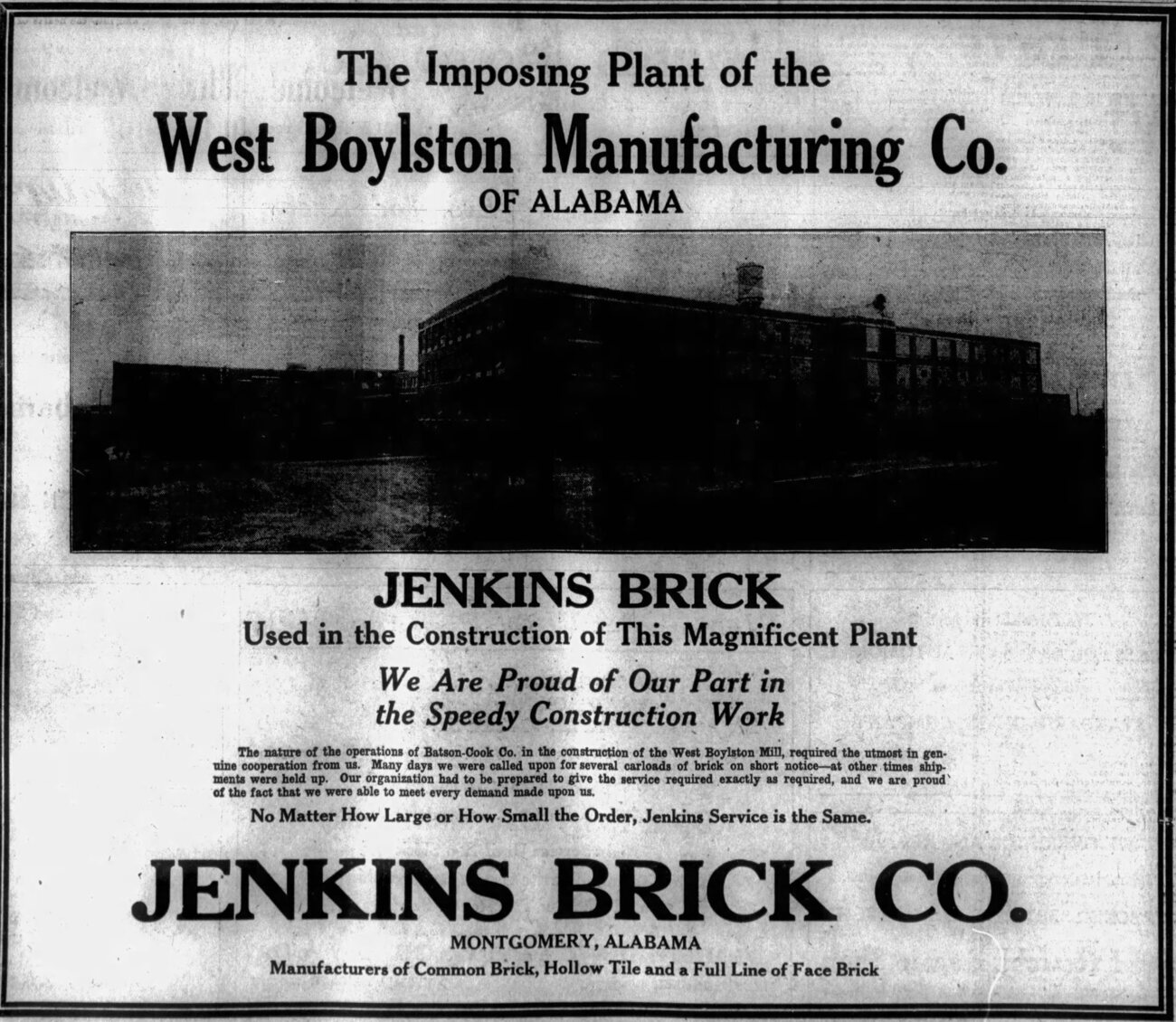

The Jenkins Brick Company was founded in 1899 by John Michael Jenkins in Wetumpka, Alabama. After losing a leg working as an engineer for the Louisville & Nashville Railroad, Jenkins began making and selling brick beehive ovens. As the business grew, he found it more profitable to produce his own bricks using the “stiff-mud process” in which raw clay was crushed, tempered, extruded, and cut into bricks. He found a market for his stiff-mud bricks and incorporated the Jenkins Brick Company on January 1, 1906, with a capital stock of $75,000. Over 85% of the company stock was owned by the citizens of Wetumpka.

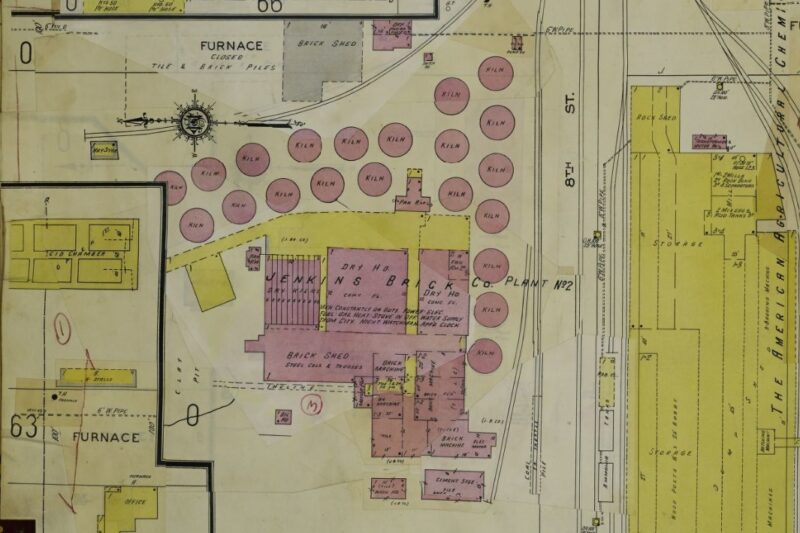

The same year the company was incorporated, substantial alluvial acreage of good-quality clay was purchased on the Alabama River adjacent to Montgomery, and a semi-continuous kiln was installed on site, now located on Furnace Street. The Wetumpka plant was improved and its efficiency and capacity were increased. Both plants had a combined capacity of 80,000 bricks per day.

Along with being President and Secretary of the company, Jenkins also served as Secretary of the Agricultural School and Experimental Station in Wetumpka, and Vice-President of the Bank of Wetumpka. He was also a Mason, Knights of Pythias, and a member of the Odd Fellows. He was also a devout member of the Methodist church. He died on April 26, 1918, after a lingering illness.

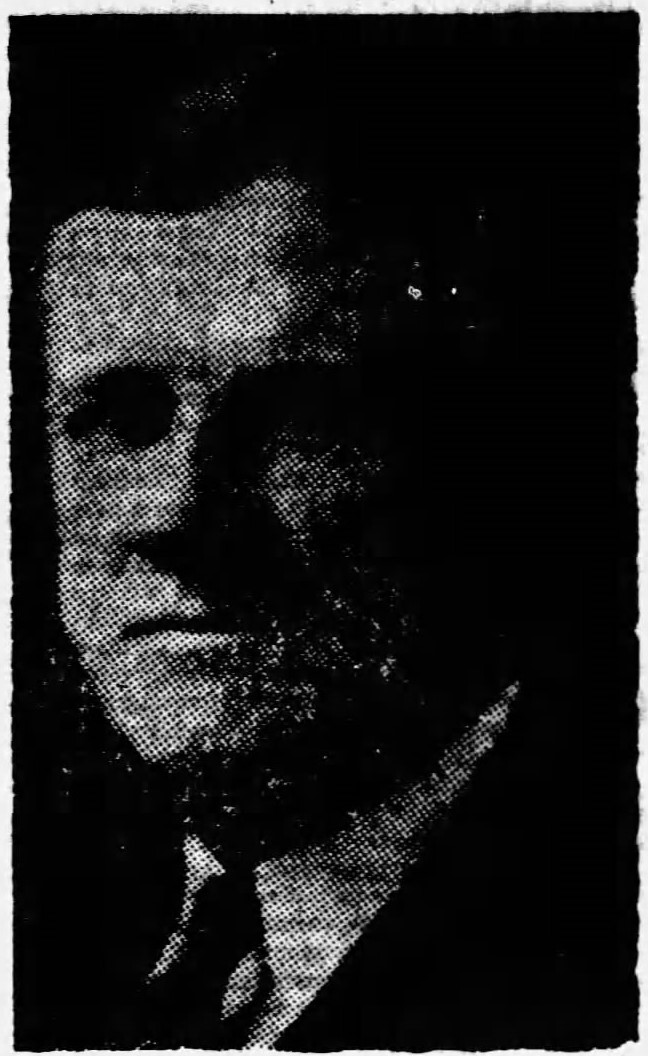

John Micheal Jenkins II

John Michael Jenkins Jr. was born on September 5, 1885, in Wetumpka. At the time, his family occupied the J. Bruce Airey House at 1202 West Tuskeena Street. After graduating from Vanderbilt University in Nashville, Tennessee in 1906, he joined his father in the newly incorporated Jenkins Brick Company. After his father’s death in 1918, he assumed the presidency of the company and it was under his guidance that the company became the largest brick distributor in the Southeast.

In 1923, he began a three-year program that replaced the old semi-continuous kiln with a new brick and tile drying and burning process called the Minter System. The Minter System was developed in Columbus, Georgia by Maurice Martin Minter between 1920 and 1930, and gained widespread popularity amongst factories across the United States and Canada. The system operated on down-draft kilns connected by underground flues and burned the brick from the top down by avoiding direct firing. “The heat was directed from fireboxes to the arched crown via flues in the walls or baffles in front of the firebox, dispersing the heat evenly over the inside of the kiln.”

The Minter System allowed for a variety of things to be burned in the kilns, including bricks, hollow blocks, tubes, and pipes, and utilized waste heat generated in the burning phases. The factory saw the installation of 18 new Minter Syestem kilns between 1923 and 1927 and added its last two in 1941. These kilns were used until the closure of the Furnace Street plant in the 1970s.

John Michael Jenkins Jr. died on November 20, 1956. At the time of his death, he was the vice president of the Shepard Building Company and served on the board of control of the Brick Manufacturers Association. He served as president of the local Rotary Club, president of the Montgomery Chamber of Commerce, and chairman of the Montgomery Board of Revenue from 1941 to 1946. He was also a member of the Alabama Chamber of Commerce.

The Jenkins Brick Company still operates distribution facilities in Alabama, Georgia, Florida, Tennessee and South Carolina, and perates manufacturing plants in Montgomery, Coosada, and Moody. Employment peaked at around 650 in 2007 before the collapse of the housing market. In January 2011, it was announced that Jenkins Brick was acquired by Acme Brick, the country’s largest brick producer and distributor. Much of the old Jenkins Brick Company Plant No. 2 on Furnace Street in Montgomery is demolished with just one of the Minter System kilns remaining, and is also one of the last in existance. In 1999, the property was documented by photographer Jet Lowe in association with the Historic American Engineering Record.